Material Options / Dillidur

WEAR-RESISTANT STEEL IS A MATTER OF TRUST

Large manufacturers ofconstruction machinery have to work hard to earn their good reputation: extra-ordinary eflÓciency and long service life of their products- along with excellent service. But it is also a well-known fact that valuable equipment is worn out in its rough contact with earth and stone more in the construction industry Ihan in any other fyeld. This is the reason why Ihe quality of excavators, earthmovers or conveying equipment is particularly dependent upon the materials of which they are made. Nowadays our steels combine properties which in the past couldn't be combined: high degree of wear resistance with thinner plates and excellent fabrication properties.

Good materials are a prerequisite, but that alone is not enough. The excellent service otfered to its customers by construction machinery manufacturers depends also on the cooperation with their suppliers. The Dillinger H¸tte GTS steelworks has attained a great level of trust particularly in this fyeld. From wear plates through to a complete dredger shovel - an ever increasing number of large construction machine manufacturers are deciding to have their wear affected machine parts made of DILLIDUR 400 V.

GIVE YOUR DESIGNERS SUPPORT

Cutting edges of shovels, grabs and scoops are subjected to extreme abrasion wear loading, which "normal" steels can't withstand in the long term. In such cases you need a particular microstructuye and special hardness. The same situation is encountered with tipping skips or rock chutes. Until recently it was hardly possible to subject components such as these to the demands placed on modern machinery. To the dismay of design engineers, conventional wear-resistant steel grades with their complicated processing instructions didn't permit complicated design.

Modern wearresistant steels such as DILLIDUR 400 V, on the other hand, are hardened by means of a special heat treatment, instead ofan alloying process. And this is the reason why DILLIDUR 400 V is not only hard but also tough even down to low-temperature applications. Thanks to their low alloy content the steels are easy to process in spite of their hardness. Now design engineers of construction machinery are fynally in a position to do what they have always wanted: to slim down their designs while at the same time improving the wear resistance wherever this is necessayy. Do your design engineers a favour by letting them have DILLIDUR 400 V.

HELP YOUR COMPANY TO SAVE COSTS

Because the service life of every wear part comes to an end sooner or later, the good processing qualities of DILLIDUR 400 V make this steel remarkable for repairwork. While in the past, whole structural components had to be replaced, now the use of DILLIDUR 400 V permits the simple repair of only the worn-out sections of the part.

The steel is well suited to cold forming. It is easy to cut and to weld. In many cases the affected section only has to be burned out and replaced with a new and, where necessary, preformed plate. This causes no problem if the welding instructions for DILLIDUR 400 V are observed.

These can be found in ourbrochure "Technicallnformation DILLIDUR". When required, screwed connections can also be simply used, since DILLIDUR 400 V can be easily machined. By choosing this steel you reduce the downtime and repair costs ofyour construction machinery.

THE DILLIDUR RANGE

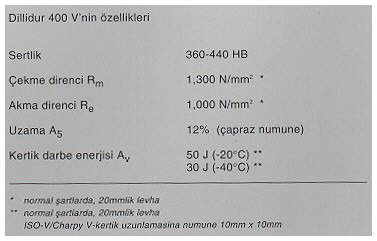

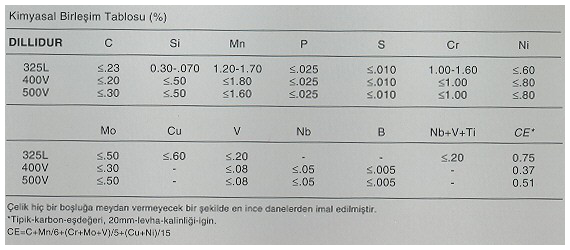

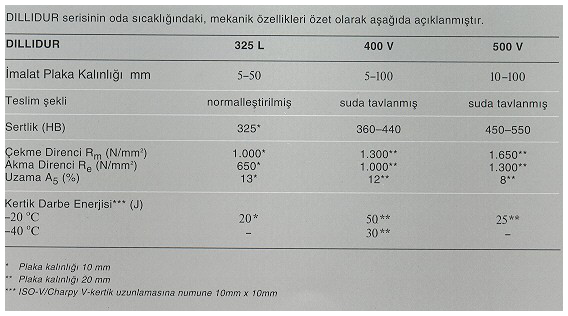

In addition to DILLIDUR 400 V, we would also like to introduce to you two other steel types from the DILLIDUR range. DILLIDUR 500 V was developed for the highest wear resistance. Naturally welding and machining operations here involve a little more effort than with the "milder' DILLIDUR 400 V. We recommend DILLIDUR 325 L for wear-resistant components which must be hot formed or operated at high temperatures. The properties of all three steels are summarized below. Another product in this range is the unalloyed wear-resistant steel type DILLIDUR 275 U, which can be supplied upon request.

AND TO MAKE THINGS EVEN EASlER FOR YOU

Here's an inside tip... Our brochure "Technical Iyyformation DILLIDUR" provides you with data on the processing of DILLIDUR. Further and more detailed information can be found in our technical sheets available at your steel stockist. However, should you have any problems with the handling of DILLIDUR, you can contact our service fax day or night. Please pass this number on to your engineers:

(+49-68 31) 47-30 89 We'll get back to you promptly.

In this way, the technical experts are in direct contact with each other while you can concentrate fully on your own tasks and responsibilities.

Leave future availability up to us.

Anyone responsible for the purchasing of wear-resistant steel grades wants to be sure that replacement material can be obtained in good time. Please let your engineers know, that you can always supply them with DILLIDUR in suff cient quantities. This is arranged by the extensive sales system and the delivery contracts, which Dillinger H¸tte GTS has concluded with a multitude ofsteel stockists - including yours. In an emergency he can even supply you with DILLIDUR at short notice. If required, the steel can be supplied in cut foym, blasted, primed and ready to weld.

WE MAKE THE STEEL

If you wish to order DILLIDUR 400 V or other steels from the DILLIDUR range, or if you simply want more information on these materials, then please get in touch with one of the sales organizations of Dillinger H¸tte GTS. Smalley amounts can also be obtained directly from your steel stockist.